Third Log Project

Posted: Tue Jul 22, 2014 8:08 am

Hello everyone,

After using this great forum for a lot of helpful research, I managed to successfully add a third log to my boat. So I took a few photos along the way and created this thread to share my experience and contribute some info. And of course I'm always looking for suggestions and ideas.

I hadn't planned on doing this project at all until I happened to score a 20' x 25" pontoon for free. The boat is a 22' Odyssey with 23" logs and a 40 horse Suzuki. First off, I understand this boat is underpowered and I didn't convert to a tritoon with the intention of pulling a pyramid of skiers with a 40. The price was obviously right, and the improved ride and load capacity is what I was aiming for. However, repowering with a 115-150 in the future is now an option I never before considered with this boat.

Here it is the day I brought it home.

After a lot of thinking, and trying to keep costs down, I opted to mount the entire 20' log underneath, and modify the motor pan to fit around it. I was also somewhat limited to how I positioned the pontoon in order to bolt it to as many crossmembers as possible. The problem was that the new pontoon had staggered risers that lined up with 24"-on-centre crossmembers. The Odyssey has continuous risers and crossmembers at every 16". I learned that this Forest Bay Odyssey is a much better built boat than whatever this new pontoon came from.

Motor removed.

Pan removed and measured to line up. The total length from the tip of of the pontoon to the transom had to be 157" in order for the pan to bolt back up to the original holes. I wanted it this way so I wouldn't have to modify the steering cable or wires or fuel line, etc. Also, the pan was engineered to mount in that place with the bulk of the weight on a 2" square tube.

Had to use some math here. There was a handy calculator from this site (http://www.mathopenref.com/arcradius.html) where I just had to take a couple measurements to find the radius of each of the three circles that had to be welded. ie. the end of the pontoon is convex and the pan had to be cut to fit it.

After measuring 100 times to make sure it was correct, I made the cuts with a sawzall. The cutting was easy, despite burning through 3 or 4 blades.

Lined everything up and it's pretty dang close. Success!

I built a jig out of scrap wood to hold everything in the exact place it was to be welded. Then I trailered it to town and had a well known welding shop stick them together.

The shop did an excellent job and added some extra gussets on the top for added strength.

Next was getting it under the boat. I tapes pieces of cardboard to the trailer to prevent scratches and it worked great.

I forgot to take pictures, but I lifted the pontoon into place using two ratchet straps hooked to the side logs. That way, raising and lowering was done easily and precisely. Once held in place and centered, I marked where to drill holes with a Sharpie and lowered it down. Long story short, I drilled a ton of holes and got it back into place and bolted it in. This was a major pain in the ass. I parked on the lawn to make it softer while spending many hours crawling around under the trailer and bumping my head. This job would have been WAAAAYYYY easier without having the deck on there.

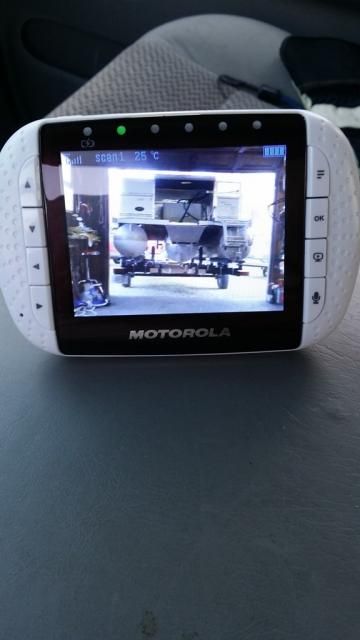

Backing up the trailer to the garage to remount the motor. I borrowed the kid's video baby monitor to give me a second set of eyes.

All done and in the water.

Later I'll try to find some before pictures compared to now to see how it sits in the water. According to the waterline stains, the boat sits somewhere between 3-5" higher now.

By comparison, my boat used to sit inches lower than that 25' Suntracker beside it in the pic above. The decks are now about level, but I'll point out though that the Tracker has some weirdly tall risers that lift the deck well above the logs.

Performance

I immediately noticed how much more stable the boat had become. Simply stepping on and off the dock is much different now. The next day I had 6 adults on board (most of them heavy) and at one point had my 5 passengers all on port side. The boat was moderately tipped, but before with only 2 pontoons I would have had to make captains orders to move people around. Also tried all 5 passengers with coolers on the front seats, and she was far from submarining even when backing off the throttle.

Cavitation/ventilation was a concern of mine, given that the 20" shaft motor is only about 32" behind the 26"-deep centre pontoon. I tried to figure out ahead of time how that would play out, but there are too many variables for this small brain to calculate on paper. The plan was, if the motor sucked air I'd mount a jackplate which would set the motor a few inches back and then I could lower it a couple more inches. Also, I spend 99% of the time putting around a 3 mile lake at 5 mph. So ventilation would rarely be a problem anyway. Later on, I'd upgrade to a 25" shaft motor.

Full throttle, no ventilation! It does suck air while full throttle and turning sharp (sharp by a pontoon's standards). Really, this will not be an issue. Top speed was barely affected, if at all. The boat still ripped at a lightning 16-17 mph with a 9 pitch prop.

Overall, I'm thrilled with the results. It rides like a whole new boat with its stability and buoyancy. The boat is rated for a 115 and someday I'd like to get one (or maybe go a little bigger).

Total cost:

20' x 25" pontoon - Free

Professional welding - $240

Stainless hardware - $60

Ruined saw blades - $30

Total - $330

Hope this helps others in some way. Any question/suggestions, please share!

LC.

After using this great forum for a lot of helpful research, I managed to successfully add a third log to my boat. So I took a few photos along the way and created this thread to share my experience and contribute some info. And of course I'm always looking for suggestions and ideas.

I hadn't planned on doing this project at all until I happened to score a 20' x 25" pontoon for free. The boat is a 22' Odyssey with 23" logs and a 40 horse Suzuki. First off, I understand this boat is underpowered and I didn't convert to a tritoon with the intention of pulling a pyramid of skiers with a 40. The price was obviously right, and the improved ride and load capacity is what I was aiming for. However, repowering with a 115-150 in the future is now an option I never before considered with this boat.

Here it is the day I brought it home.

After a lot of thinking, and trying to keep costs down, I opted to mount the entire 20' log underneath, and modify the motor pan to fit around it. I was also somewhat limited to how I positioned the pontoon in order to bolt it to as many crossmembers as possible. The problem was that the new pontoon had staggered risers that lined up with 24"-on-centre crossmembers. The Odyssey has continuous risers and crossmembers at every 16". I learned that this Forest Bay Odyssey is a much better built boat than whatever this new pontoon came from.

Motor removed.

Pan removed and measured to line up. The total length from the tip of of the pontoon to the transom had to be 157" in order for the pan to bolt back up to the original holes. I wanted it this way so I wouldn't have to modify the steering cable or wires or fuel line, etc. Also, the pan was engineered to mount in that place with the bulk of the weight on a 2" square tube.

Had to use some math here. There was a handy calculator from this site (http://www.mathopenref.com/arcradius.html) where I just had to take a couple measurements to find the radius of each of the three circles that had to be welded. ie. the end of the pontoon is convex and the pan had to be cut to fit it.

After measuring 100 times to make sure it was correct, I made the cuts with a sawzall. The cutting was easy, despite burning through 3 or 4 blades.

Lined everything up and it's pretty dang close. Success!

I built a jig out of scrap wood to hold everything in the exact place it was to be welded. Then I trailered it to town and had a well known welding shop stick them together.

The shop did an excellent job and added some extra gussets on the top for added strength.

Next was getting it under the boat. I tapes pieces of cardboard to the trailer to prevent scratches and it worked great.

I forgot to take pictures, but I lifted the pontoon into place using two ratchet straps hooked to the side logs. That way, raising and lowering was done easily and precisely. Once held in place and centered, I marked where to drill holes with a Sharpie and lowered it down. Long story short, I drilled a ton of holes and got it back into place and bolted it in. This was a major pain in the ass. I parked on the lawn to make it softer while spending many hours crawling around under the trailer and bumping my head. This job would have been WAAAAYYYY easier without having the deck on there.

Backing up the trailer to the garage to remount the motor. I borrowed the kid's video baby monitor to give me a second set of eyes.

All done and in the water.

Later I'll try to find some before pictures compared to now to see how it sits in the water. According to the waterline stains, the boat sits somewhere between 3-5" higher now.

By comparison, my boat used to sit inches lower than that 25' Suntracker beside it in the pic above. The decks are now about level, but I'll point out though that the Tracker has some weirdly tall risers that lift the deck well above the logs.

Performance

I immediately noticed how much more stable the boat had become. Simply stepping on and off the dock is much different now. The next day I had 6 adults on board (most of them heavy) and at one point had my 5 passengers all on port side. The boat was moderately tipped, but before with only 2 pontoons I would have had to make captains orders to move people around. Also tried all 5 passengers with coolers on the front seats, and she was far from submarining even when backing off the throttle.

Cavitation/ventilation was a concern of mine, given that the 20" shaft motor is only about 32" behind the 26"-deep centre pontoon. I tried to figure out ahead of time how that would play out, but there are too many variables for this small brain to calculate on paper. The plan was, if the motor sucked air I'd mount a jackplate which would set the motor a few inches back and then I could lower it a couple more inches. Also, I spend 99% of the time putting around a 3 mile lake at 5 mph. So ventilation would rarely be a problem anyway. Later on, I'd upgrade to a 25" shaft motor.

Full throttle, no ventilation! It does suck air while full throttle and turning sharp (sharp by a pontoon's standards). Really, this will not be an issue. Top speed was barely affected, if at all. The boat still ripped at a lightning 16-17 mph with a 9 pitch prop.

Overall, I'm thrilled with the results. It rides like a whole new boat with its stability and buoyancy. The boat is rated for a 115 and someday I'd like to get one (or maybe go a little bigger).

Total cost:

20' x 25" pontoon - Free

Professional welding - $240

Stainless hardware - $60

Ruined saw blades - $30

Total - $330

Hope this helps others in some way. Any question/suggestions, please share!

LC.