Page 1 of 1

leaking toon???

Posted: Thu Feb 21, 2013 9:26 am

by bentleyjc

Buddy of mine has an older pontoon and one of the toons has a slow leak. Whats the best way to find the culprit area and fix it somehow (cost effective of course)?

thanks!

Re: leaking toon???

Posted: Thu Feb 21, 2013 9:37 am

by The_Hellbilly

1. Pressurize the toon to approx. 2psi with a small pump or shopvac DO NOT OVER PRESSURIZE, THEY WILL EXPLODE

2. get a squirt bottle with soapy water and start spraying the welds & seams

3. look for bubbles

Take it to a local welder to get it fixed. I don't recommend using any JB weld type products

Re: leaking toon???

Posted: Thu Feb 21, 2013 9:45 am

by HandymanHerb

What he said

Re: leaking toon???

Posted: Thu Feb 21, 2013 9:47 am

by badmoonrising

Yep ^.

Re: leaking toon???

Posted: Thu Feb 21, 2013 10:04 am

by bentleyjc

thanks guys - glad you said 2psi because he and I were talking about it earlier today and we were on the right path but we were talking about getting an air compressor and shooting air in it then spray it down... may have shot a lil too much in it doing that

Re: leaking toon???

Posted: Thu Feb 21, 2013 10:57 am

by curtiscapk

You can use shop vac or lawn blower with some kind of hose.

Re: leaking toon???

Posted: Thu Feb 21, 2013 12:33 pm

by The_Hellbilly

bentleyjc wrote:thanks guys - glad you said 2psi because he and I were talking about it earlier today and we were on the right path but we were talking about getting an air compressor and shooting air in it then spray it down... may have shot a lil too much in it doing that

someone around here has a video of a pressurized toon exploding. I'll see if I can find it.

Re: leaking toon???

Posted: Thu Feb 21, 2013 3:56 pm

by Nusse

I have worked with quality claims at a pneumatic manufacturer.

2 PSI would work (although I'd go for Bar LOL).

There are 3 ways to determine the leaks.

1. Buy leak spray (expensive)

2. Use soap water. Mix hand dishing detergent with water. Use a hand sprayer.

3. This is the best version.....

Dip the whole piece pressurized into a tank or why not the lake and it will show you if there is more then 1 place leaking. By submerging it in water you may not only find that it is leaking in more then 1 place ( saves you going several times to the welder shop) but you can also quantify the leakage by taking a meter glass, fill it with water, turn it upside-down still submerged under the water. Then, move the upside-down meter glass over the leaking bubbles and collect the bubbles. This will give you the cubic-whatever cm/inch a minute the leak is.

Cheers,

Re: leaking toon???

Posted: Fri Feb 22, 2013 8:30 am

by jimrs

Nusse wrote:I have worked with quality claims at a pneumatic manufacturer.

2 PSI would work (although I'd go for Bar LOL).

There are 3 ways to determine the leaks.

1. Buy leak spray (expensive)

2. Use soap water. Mix hand dishing detergent with water. Use a hand sprayer.

3. This is the best version.....

Dip the whole piece pressurized into a tank or why not the lake and it will show you if there is more then 1 place leaking. By submerging it in water you may not only find that it is leaking in more then 1 place ( saves you going several times to the welder shop) but you can also quantify the leakage by taking a meter glass, fill it with water, turn it upside-down still submerged under the water. Then, move the upside-down meter glass over the leaking bubbles and collect the bubbles. This will give you the cubic-whatever cm/inch a minute the leak is.

Cheers,

How do you proprose to submerge the toon to find the leak? Who cares about the amount of leakage if it's leaking then it need to be fixed no matter what the quanity of leak is. A leaking toon will eventually sink no matter how small the leak is.

Re: leaking toon???

Posted: Fri Feb 22, 2013 2:18 pm

by slingshot

Nusse wrote:I have worked with quality claims at a pneumatic manufacturer.

2 PSI would work (although I'd go for Bar LOL).

There are 3 ways to determine the leaks.

1. Buy leak spray (expensive)

2. Use soap water. Mix hand dishing detergent with water. Use a hand sprayer.

3. This is the best version.....

Dip the whole piece pressurized into a tank or why not the lake and it will show you if there is more then 1 place leaking. By submerging it in water you may not only find that it is leaking in more then 1 place ( saves you going several times to the welder shop) but you can also quantify the leakage by taking a meter glass, fill it with water, turn it upside-down still submerged under the water. Then, move the upside-down meter glass over the leaking bubbles and collect the bubbles. This will give you the cubic-whatever cm/inch a minute the leak is.

Cheers,

Right, just drive a school bus onto your toon in shallow water then check for leaks. simple really.

Re: leaking toon???

Posted: Sat Feb 23, 2013 5:32 pm

by Nusse

I should have been more precise.

I dont mean to submerge the whole boat. Just the log. And I don't mean the whole log at one time but side by side. Now that may be tricky if it is still attached to the rest of the boat. But if it is removable then....

Guess the whole idea was to find if there is more the one leakage. To quantify it - well you may have a micro leakage. Not even car tires are completely leak free. You may be surprised what leakage is found and then you will know which leaks to concentrate on fixing.

Re: leaking toon???

Posted: Sun Feb 24, 2013 10:27 am

by RonKMiller

Wow, tough crowd here. I guess dogma dies a very slow death.

I'll have to agree that submerging is the BEST, SAFEST and

only foolproof way to find leaks. That's exactly what I did with mine when I took ownership of my derelict 1988 Party Hut - and before I started a year long build.

It's EASY to submerge one side at a time by simply piling sandbags on that side, it took 20 (a bit over 2,000 lbs. since I had the large size) to

completely submerge mine. Sand is cheap, sandbags are cheap. I hired a couple of teenagers to fill 'em and pile 'em on while I drank beer. Look for the bubbles, then jump in with a dive mask and circle the spot(s) with a black wax dish marking pencil.

- sandbags.jpg (410.62 KiB) Viewed 18460 times

If you went the pressurization route Leak-Tek detection spray is dirt cheap and FAR superior to soapy water. It's what professionals use. It will provide LOTS of bubbles on even the smallest leak. A lot of the leaks come from cracked welds where the log attaches to the mounting bracket - they're sometimes almost impossible (especially on the inside of the bracket) to see without a telescoping inspection mirror and bright flashlight.

Re: leaking toon???

Posted: Sun Feb 24, 2013 3:46 pm

by Nusse

Thank you for the support RonKMiller.

Re: leaking toon???

Posted: Mon Feb 25, 2013 6:57 am

by RonKMiller

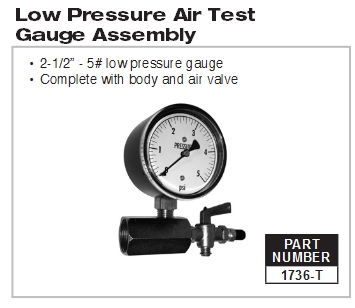

Another quick way to check for problems and one that is

very reliable is a simple leak down test with a low pressure test gauge.

Simply pressurize each chamber to 2 or 3 psi and see if the needle moves down. I would give it 15 minutes and keep the log out of the sun while testing on a cool day. You may need to adapt some common plumbing hardware to mount to your bung but it already has a Schraeder valve on one side. If it doesn't hold pressure you now need to do further investigation by either submerging or spraying with leak detector. Make

sure the gauge and hardware connection with the valve of your log doesn't leak by spraying it right after you pressurize it, you may need to use a wrap of Teflon tape.

Here's one from

http://www.pascospecialty.com/products.php that should work perfectly. The little ball valve is especially nice to have since you can meter the EXACT amount of air flowing into the log instead of doing it in spurts.

- low pressure test gauge.jpg (49.31 KiB) Viewed 18236 times

I've got the 15 psi version which is also acceptable since it reads in 1/10 psi.

Either one should be around $20.00.

Re: leaking toon???

Posted: Mon Feb 25, 2013 7:57 am

by Nusse

[quote="RonKMiller"]Another quick way to check for problems and one that is very reliable is a simple leak down test with a low pressure test gauge.

Simply pressurize each chamber to 2 or 3 psi and see if the needle moves down. I would give it 15 minutes and keep the log out of the sun while testing on a cool day. You may need to adapt some common plumbing hardware to mount to your bung but it already has a Schraeder valve on one side. If it doesn't hold pressure you now need to do further investigation by either submerging or spraying with leak detector. Make sure the gauge and hardware connection with the valve of your log doesn't leak by spraying it right after you pressurize it, you may need to use a wrap of Teflon tape.

quote]

It is a good way, just be carefull with the Schaeder Bellows valve.

1. All valve leak (more or less) even a new valve has a allowed leakage (specification) in order to pass the EOL-test at the manufacturer. The small leak of the valve may show you more leak then you actually have over the logs.

2. Schrader quality - well I am not going to go there.

3. Considering the very large volume of the log. I would perhaps even use more time to see if there is a pressure drop. A few hours at least.

Cheers,